I will admit, I do not like the titles …for dummies. But, I do love teaching about PID controllers and this title seems to be a popular go-to when people are looking for an easy to follow explanation. Well.. here we go!

PID – Proportional Integral Derivative

A PID controller is a controller used in automation to control an output and bring a process value to the desired set point.

The PID controller does this by monitoring a specific input (the process value), calculating how far away it is from the set point, and using this information to calculate the output.

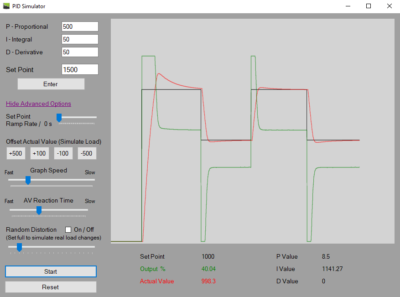

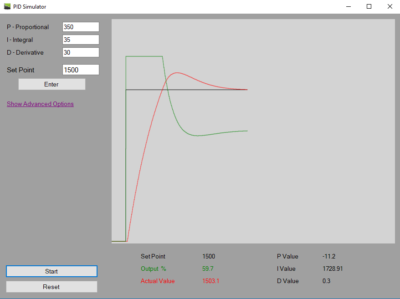

Check out the PID Simulator page to use a live PID Simulator!

Basic PID Example

Below is a basic, but easy to understand example of a PID controller in real life.

In this example;

Process value = vehicle speed

Set point = cruise control set point

Output = throttle valve

You are driving down the highway and decide to turn on cruise control at 100 km/h. When your vehicle comes to a hill, the speed drops below the set point.

In this example, the set point is 100 km/h, the actual speed drops to 70 km/h, so the error value becomes 100 – 70 =30.

The PID controller takes in this error value, and determines how much to control the output, to bring the process value to the desired set point.

The PID controller will calculate the Error value, then press down on the gas pedal until your car reaches the 100 km/h set point (the error becomes zero).

Read “PID Controller Explained!” for an in depth look at how a PID controller works, or check out the video below.